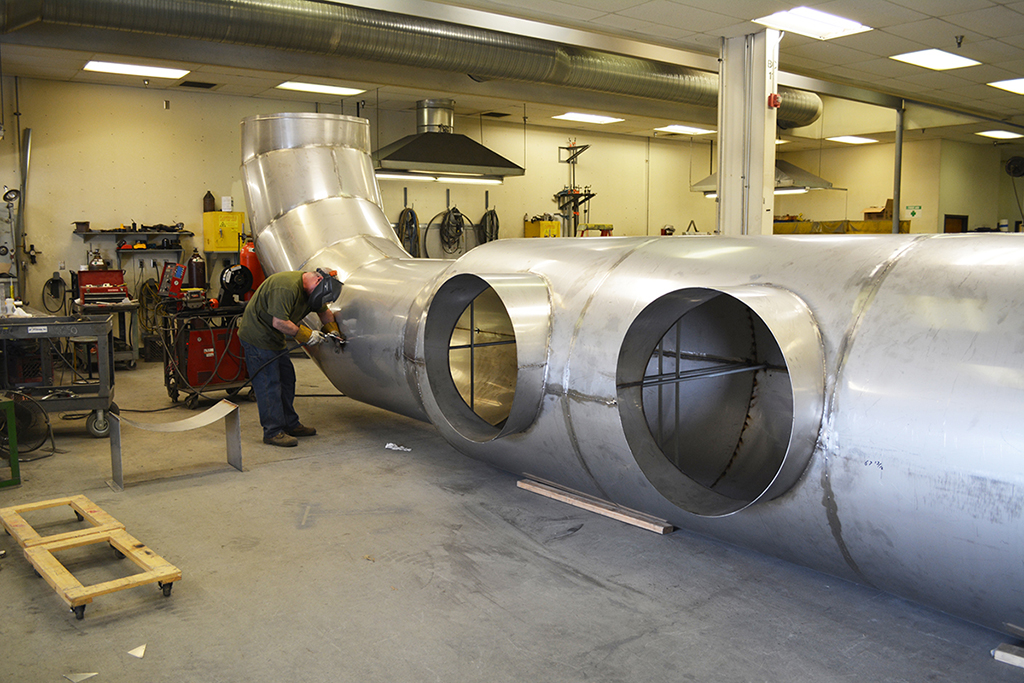

P1 Group Fabrication Creates Maximum Efficiency

Make it and take it! Efficiency is the name of the game, and that’s why P1 Group invests in four fabrication shops at our 220,000 sq ft warehouse space in Lawrence, KS. Fabrication gives P1 Group yet another edge in our diversified capabilities.

“The fabrication shop plays an integral role in the efficiency of certain jobs,” Vice President Paul Smith said. “Fabricating in our own controlled environment reduces labor cost, decreases installation time and ensures the highest level of quality assurance/quality control.”

Bottom line? Because of the fabrication shop, P1 Group can build it faster and customers get quality-ensured products at a lower price.

Also housed within the Lawrence warehouse space is a separate tool shop that serves all of P1 Group’s fabrication and field work.

At a Glance…

Electrical Fabrication Shop: 15,900 sq ft

Stainless Pipe Shop: 15,000 sq ft + Carbon Pipe Shop: 12,000 sq ft

Sheet Metal Fabrication Shop: 15,000 sq ft for fabrication + 10,000 sq ft for preassembly

The fabrication shop:

- reduces on-site manpower by 25 to 50 percent

- reduces on-site packaging waste

- allows P1 Group to meet tight timelines

- creates Quality Assurance/Quality Control:

indoor controlled environment eliminates outdoor element damage

designated QA/QC manager inspects every piece of fabrication for accuracy and quality

Did You Know…

- The electrical fab shop recently relocated within the building, increasing fabrication space by about 5,400 sq ft.

- The sheet metal fab shop can manufacture a standard length of duct in about 30 seconds with its coil line equipment.

- The pipe fab shop can work with almost any material and fabricates pipes as large as 60 inches+ - big enough to walk in!

- The massive tool shop located in the Lawrence warehouse space is approximately 23,000 sq ft ↓

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.